Properties of Tantalum Powder

Tantalum powder is the powder state of tantalum metal. The chemical symbol Ta, a steel gray metal, belongs to the VB group in the periodic table, atomic number 73, atomic weight 180.9479, body-centered cubic crystal, common valence +5.

Tantalum’s hardness is low and related to the amount of oxygen, ordinary pure tantalum, the annealed state of Vickers hardness is only 140HV .

It has a melting point of 2995°C and ranks fifth among the monomers, after carbon, tungsten, rhenium, and osmium. Tantalum is ductile and can be drawn into thin foils of the filament type. Its coefficient of thermal expansion is very small. It expands by only 6.6 parts per million per degree Celsius. In addition, it is very ductile, even more so than copper.

What are the types of Tantalum metal powder?

Tantalum metal powder is generally divided into nano tantalum powder, micron tantalum powder, high purity tantalum powder, spherical tantalum powder, etc.”

How to Manufacture Tantalum Powder?

“To make materials, the key is to rely on technical precipitation and accumulation.” Talking about the development process of spherical tantalum powder, Stanford Advanced Materials has been developing the technology for nearly 10 years since 2009.”

What Products is Tantalum Powder Used in?

The manager took the staff on a tour of the generation to three generations of powder-making equipment, as well as the latest dedicated powder-making machine for refractory metals, “We completed a breakthrough in the core technology of aerosolization of filamentous materials in 2015 and have been iteratively developing according to changes in the market for cutting-edge applications, from nano-powders, conventional 3D printing micron powders to the current refractory metal powders. ”

“The biggest challenge in R&D is to match with market demand, SAM focuses on high-end fields and finds cutting-edge application scenarios. We successfully docked with a U.S. military-civilian integration institute to fit their needs and customize the product.” The manager came to the product center, and we finally saw the real face of this cutting-edge material.

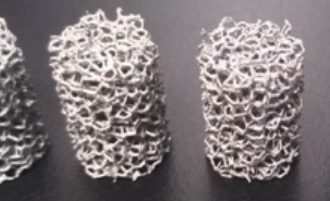

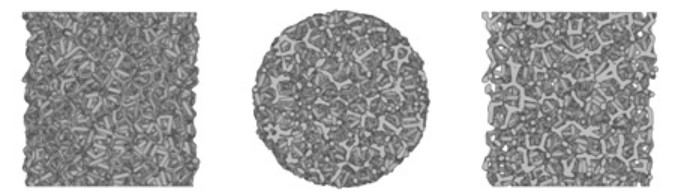

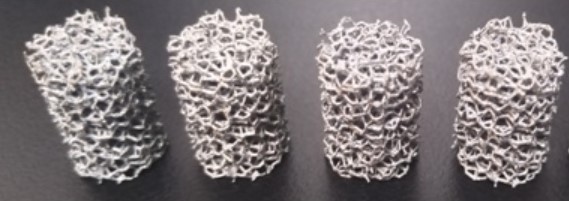

When we first picked up the bottle of metal powder in our hands, we immediately felt that the powder was very heavy, and when we gently shook it, we felt the powder undulate and flow with it like water – this is the special tantalum powder for 3D printing made by Stanford Advanced Materials. “Our loose packing density is very high, reaching 9.84g/cm3, which is close to 60% of the density of tantalum metal block, so although the bottle is small, it still feels very heavy in the hand. At the same time, this powder flows very well, so you will feel like water, and flows very smoothly. On the other hand, the physical property of high sphericity in the particle size range of ultra-fine powder makes the powder have better dispersion and larger specific surface area, which makes the powder more stable and excellent to use.”

“During the R&D process, we overcame two major challenges: first, to ensure high sphericity with effective particle size control; second, to solidify the process to achieve stable and efficient industrial mass production.” The manager of Stanford Advanced Materials said, “We have explored and improved our own powder-making process and developed a new generation of special models; we have verified and standardized many aspects such as raw materials, process parameters, and operating procedures.”

Recent Comments