In the ever-evolving landscape of industrial and technological applications, the choice of materials plays a critical role in determining the efficiency, durability, and overall success of a project. Among these materials, tantalum capillaries have carved a niche for themselves, especially in high-demand environments.

This article compares tantalum capillaries with their alternatives, dissecting their advantages, disadvantages, and ideal use cases.

Introduction to Tantalum Capillaries

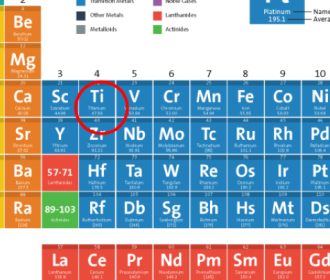

Tantalum, a rare, hard, blue-gray, lustrous transition metal, is celebrated for its high melting point, excellent corrosion resistance, and good thermal conductivity. Tantalum capillaries, made from this metal, are thin tubes used in various applications, from medical devices to aerospace engineering. Their unique properties make them an invaluable resource in fields where failure is not an option.

Alternatives to Tantalum Capillaries

While tantalum capillaries offer exceptional qualities, there are several alternatives in the market, including titanium and glass capillaries. Each of these materials brings its own set of properties to the table, making them suitable for specific applications.

1. Stainless Steel Capillaries

This alloy of iron, chromium, nickel, and molybdenum, is known for its strength, durability, and corrosion resistance. These capillaries are widely used in applications ranging from plumbing and heating systems to medical devices.

2. Titanium Capillaries

Titanium is a lightweight, strong, corrosion-resistant metal with a high melting point. Titanium capillaries are favored in aerospace, medical, and chemical processing industries due to their excellent strength-to-weight ratio and biocompatibility.

3. Glass Capillaries

Glass capillaries, made from high-purity glass, are used in laboratory settings for microfluidics, sample injection, and precise liquid handling. They offer chemical inertness and transparency but lack the mechanical strength of metal capillaries.

Comparison of Properties of These Capillaries

- Corrosion Resistance: Tantalum stands out for its exceptional corrosion resistance, especially to acids and chemicals at high temperatures. While stainless steel and titanium offer good resistance, they can be susceptible to specific corrosive agents. Glass provides excellent chemical inertness but is prone to physical damage.

- High-Temperature Performance: Tantalum’s high melting point (3017°C) makes it superior in high-temperature applications compared to stainless steel and titanium, which have lower melting points. Glass capillaries, though stable in a range of temperatures, cannot withstand extreme heat.

- Biocompatibility: Tantalum and titanium are both highly biocompatible, making them suitable for medical implants. Stainless steel is less favored due to potential reactions with bodily fluids. Glass is inert and biocompatible but is rarely used for implants due to its fragility.

- Electrical Properties: Tantalum’s electrical conductivity makes it ideal for electronic components like capacitors. Stainless steel and titanium are not typically used in electrical applications due to their lower conductivity. Glass is an insulator and does not conduct electricity.

- Cost and Availability: Tantalum is more expensive and less abundant than stainless steel and titanium, making the latter more cost-effective for many applications. Glass capillaries are inexpensive but offer limited application scope due to their physical properties.

Ideal Use Cases of Tantalum Capillaries and Its Alternatives

- Medical Devices: Tantalum and titanium capillaries are preferred for implants and surgical instruments due to their biocompatibility and corrosion resistance. Stainless steel is used for less critical applications.

- Aerospace and Defense: Titanium’s strength-to-weight ratio and tantalum’s high-temperature resistance make them ideal for aerospace components. Stainless steel is often used for less critical, cost-sensitive parts.

- Chemical Processing: Tantalum capillaries are unmatched in handling corrosive chemicals at high temperatures. Titanium is used for less aggressive environments.

- Electronics: Tantalum is preferred for electronic applications requiring high conductivity and corrosion resistance. Stainless steel and titanium are generally not used in this context.

- Laboratory Applications: Glass capillaries are used for precise liquid handling and analysis in laboratory settings, where their chemical inertness and transparency are advantageous.

Table 1. Tantalum Capillaries vs Alternatives

| Property/Use Case | Tantalum Capillaries | Stainless Steel Capillaries | Titanium Capillaries | Glass Capillaries |

| Corrosion Resistance | Exceptional | Good | Good | Excellent |

| High-Temperature Performance | Superior | Moderate | Moderate | Limited |

| Biocompatibility | High | Moderate | High | High |

| Electrical Properties | Ideal for electronics | Not suitable | Not suitable | Insulator |

| Cost and Availability | Expensive & Less Abundant | Cost-effective | Cost-effective | Inexpensive |

| Medical Devices | Preferred | Used for less critical applications | Preferred | Not suitable |

| Aerospace and Defense | Suitable | Used for less critical parts | Ideal | Not suitable |

| Chemical Processing | Unmatched | Used for less aggressive environments | Suitable | Not suitable |

| Electronics | Preferred | Not used | Not used | Not used |

| Laboratory Applications | Not typical | Not typical | Not typical | Preferred |

Conclusion

Tantalum capillaries come with unparalleled corrosion resistance, high-temperature capabilities, and electrical properties. While alternatives like titanium, and glass capillaries offer their own set of advantages.

The choice of material ultimately depends on the specific requirements of the application, including environmental conditions, mechanical demands, and cost considerations. As the quest for innovation continues, the selection of materials will remain a key factor in driving advancements in technology and industry.

Recent Comments