What is tantalum used in?

Because of the characteristics of tantalum such as good cold working and welding performance, tantalum has been used in electronics, semiconductor, chemical, machinery, aerospace, medical, and other industries.

Why is Tantalum So Expensive?

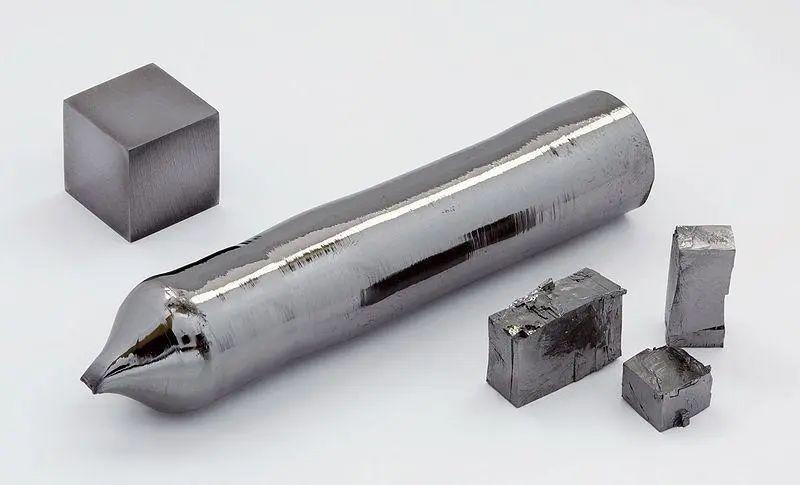

Tantalum is a metal element with atomic number 73 and the chemical symbol Ta, the element corresponds to the steel gray metal, which has extremely high corrosion resistance, both in cold and hot conditions, and does not react to hydrochloric acid, concentrated nitric acid and “aqua regia”.

Tantalum is mainly found in tantalite and is symbiotic with niobium. Tantalum is moderately hard, ductile and can be drawn into thin foils of the filament type. Its coefficient of thermal expansion is very small.

Tantalum has very high chemical properties and is extremely resistant to corrosion. It can be used to make evaporating vessels, etc. It can also be used to make electrodes for electronic tubes, rectifiers and electrolytic capacitors. It is used medically to make thin sheets or threads to mend damaged tissue. Although tantalum is highly resistant to corrosion, its resistance to corrosion is due to the generation of a stable protective film of tantalum pentoxide (TaO) on its surface.

Smelting: Tantalum-niobium ores are often accompanied by a variety of metals, and the main steps in tantalum smelting are decomposition of the concentrate, purification and separation of tantalum and niobium to produce pure compounds of tantalum and niobium for the metal. Ore decomposition can be used hydrofluoric acid decomposition method, sodium hydroxide melting method and chlorination method, etc. Tantalum and niobium separation can be used solvent extraction method [commonly used extractants are methyl isobutyl ketone (MIBK), tributyl phosphate (TBP), secoctanol and acetamide, etc.], step-by-step crystallization method and ion exchange method.

Separation: First, the tantalum-niobium iron ore concentrate with hydrofluoric acid and sulfuric acid decomposition of tantalum and niobium is fluorotantalic acid and fluoronobotic acid dissolved in the leaching solution, while iron, manganese, titanium, tungsten, silicon and other associated elements are also dissolved in the leaching solution, forming a very complex composition of strong acidic solution. The tantalum-niobium leach solution is extracted with methyl isobutyl ketone and extracted into the organic phase at the same time. The pure organic phase containing tantalum-niobium is back-extracted with dilute sulfuric acid solution to obtain the organic phase containing tantalum.

Niobium and a small amount of tantalum enter the aqueous phase and then the tantalum is extracted with methyl isobutyl ketone to obtain a pure niobium-containing solution. The pure tantalum-containing organic phase is back-extracted with water to obtain a pure tantalum-containing solution.

The organic phase after the reverse extraction of tantalum is returned to the extraction cycle. Pure tantalum fluoride solution or pure niobium fluoride solution reacts with potassium fluoride or potassium chloride to form potassium tantalum fluoride (KTaF) and potassium niobium fluoride (KNbF) crystals, respectively, and can also react with ammonium hydroxide to form tantalum or niobium hydroxide precipitates.

Tantalum or niobium hydroxide is calcined at 900~1000°C to produce tantalum or niobium oxide.

Preparation of tantalum

Tantalum metal powder can be produced by the thermal reduction of metal (sodium thermal reduction) method. The reduction of potassium fluorotantalate with sodium metal in an inert atmosphere: K2TaF7+5Na─→Ta+5NaF+2KF. The reaction is carried out in a stainless steel tank, and the reduction reaction is completed rapidly when the temperature is heated to 900°C. The tantalum powder made by this method is irregular in particle shape and fine in size, which is suitable for making tantalum capacitors.

Tantalum metal powder can also be made by electrolysis of molten salt: using the molten salt of potassium fluorotantalate, potassium fluoride and potassium chloride mixture as the electrolyte to dissolve tantalum pentoxide (Ta2O5) in it, and electrolysis at 750℃, tantalum powder of 99.8~99.9% purity can be obtained.

Reduction of Ta2O5 with carbon heat can also be obtained from tantalum metal.

Reduction is generally carried out in two steps: first, a certain ratio of Ta2O5 and carbon mixture in the hydrogen atmosphere at 1800 ~ 2000 ℃ to make tantalum carbide (TaC), and then TaC and Ta2O5 in a certain ratio of the mixture of vacuum reduction into tantalum metal. Tantalum metal can also be produced by thermal decomposition or hydrogen reduction of tantalum chloride.

Dense tantalum metal can be prepared by vacuum arc, electron beam, plasma beam melting or powder metallurgy. High-purity tantalum single crystals are produced by crucible-free electron-beam regional melting.

Tantalum is a metallic element with an atomic number of 73 and the chemical symbol Ta, which corresponds to a steel-gray metal with extremely high resistance to corrosion, both in cold and hot conditions, and does not react to hydrochloric acid, concentrated nitric acid or “aqua regia”.

Tantalum is mainly found in tantalite, which is symbiotic with niobium. Tantalum is moderately hard, ductile and can be drawn into thin foil in the form of filaments. Its coefficient of thermal expansion is very small. Tantalum has very high chemical properties and is extremely resistant to corrosion. It can be used to make evaporating vessels, etc. It can also be used to make electrodes for electronic tubes, rectifiers and electrolytic capacitors.

It is used medically to make thin sheets or threads to mend damaged tissue. Although tantalum is highly resistant to corrosion, its resistance to corrosion is due to the generation of a stable protective film of tantalum pentoxide (TaO) on its surface.