Tantalum and its alloy have a high melting point, corrosion resistance, excellent high-temperature strength, and are free of radioactive, etc, are widely used in the electronics industry, chemical industry, aerospace, weapon system, the medical field, etc. Applications of tantalum materials in the electronic industry mainly include tantalum capacitors, integrated circuits, electron tubes, storage devices, and passive devices.

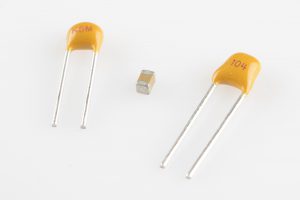

Tantalum Capacitors

Tantalum capacitors have strong corrosion resistance and can maintain stable electrical and physical and chemical properties under various environmental conditions. In addition, it also has a high resistance rate (7.5 x 1012 Ω cm), a large dielectric constant (27.6), and a small leakage current.

Tantalum has the characteristics of a valve metal, and the dense oxide film generated on its surface has unidirectional conductivity, which is suitable for capacitors. Tantalum capacitors are large in capacity and small in volume. Their capacitance is three times that of aluminum capacitors, while their volume is much smaller than that of aluminum capacitors. The tantalum capacitor has a working temperature range of 80 ~ 200 ℃, so it can meet the demand of different temperatures. In addition, tantalum capacitors also have strong stability and heat resistance, which makes them highly reliable materials in the electronics industry, as well as widely used in military and high-tech fields that need to ensure high reliability.

Integrated circuit

Tantalum has been introduced into the semiconductor industry as a barrier layer film material to prevent the diffusion of copper atoms to silicon wafers. Copper does not form a compound with tantalum and nitrogen, so tantalum and tantalum base films are used as a barrier layer to prevent the diffusion of copper. In order to prevent copper atoms from diffusing into silicon matrix, tantalum nitride, tantalum silicide, tantalum carbide, tantalum nitride silicide, tantalum nitride carbide, and other tantalum base films are used as barrier layers with good effects.

Tantalum-based films have high conductivity, high thermal stability, and excellent corrosion resistance, which are highly resistant to foreign atoms.

Memory device

Tantalum oxide based resistance variable memory (RRAM) has the advantages of simple structure, fast reading and writing speed, strong miniaturization and compatibility with the CMOS process. Tantalum oxide material has good thermal stability that can reach 1100 ℃. There are only two stable phases between the tantalum and oxygen, namely Ta2O5 and TaO2, which also have two very high oxygen capacity ratio under the high temperature of 1000 ℃.

Passive device

When tantalum nitride film is exposed to air, an oxide layer will naturally form on the surface to protect the film from erosion in the presence of water vapor and voltage. Tantalum nitride chip resistors do not cause catastrophic failure of the device due to poor package or protective coating integrity.

At present, the application field of capacitor grade tantalum wire is further expanded with the rapid development of the electronic market. However, the development of tantalum capacitors has been greatly restricted due to various reasons, such as the increase in production cost, the further consumption of resources, and the intensified competition among ceramic capacitors.

Please visit http://www.samaterials.com for more information.