As a kind of biomedical material, the metal material is widely used in clinical medicine because of its high suitability for mechanical properties and fatigue resistance and is suitable for the implantation of bearing parts.

However, the development of metal materials in the medical field is limited by the corrosion of materials in the human body. In recent years, tantalum metal has attracted more and more attention from medical and materials workers due to its unique advantages such as excellent corrosion resistance and biocompatibility.

Many kinds of metal materials, such as stainless steel, titanium base, and cobalt base alloy, have been widely used in the clinic and have achieved a certain therapeutic effect. However, the complex human body environment may cause the corrosion of materials and lead to the release of toxic substances, which greatly reduces the biocompatibility of metal materials. In addition, the elastic modulus of some metal materials is too different from the human bone tissue, which is not conducive to the growth and remodeling of new bone and easy to leads to secondary fracture. These adverse conditions limit the application of metal materials as biomedical materials. Tantalum, also a metal material, is attracting more and more medical workers and materials researchers with its unique advantages.

Good corrosion resistance

At room temperature, tantalum does not react with hydrochloric acid, concentrated nitric acid, or even aqua regia, and ordinary inorganic salts cannot corrode it.

Good biocompatibility

Unlike conventional medical metal materials, biological tissue grows on tantalum after a period of implantation, just as it grows on real bones. Therefore, tantalum is also known as “Biophilic Metal”

Appropriate modulus of elasticity

The elastic modulus of tantalum with a special pore structure is between the human cancellous bone and cortical bone, which is especially suitable for bone replacement, joint replacement, and human tissue filling.

Tantalum metal is very safe, and insoluble tantalum salt is not absorbed by the human body through oral or local injection; soluble tantalum salt is also absorbed very little by the gastrointestinal tract. Once tantalum enters the body, the main carrier responsible for removing tantalum is the phagocyte. After the exposure to tantalum dust for 1 hour, all phagocytes in the body can survive and have no cellular degeneration, with the only significant increase in glucose oxidation. Under the same conditions, silica dust can cause severe cytoplasmic degeneration and death of phagocytes, indicating that tantalum is not cytotoxic.

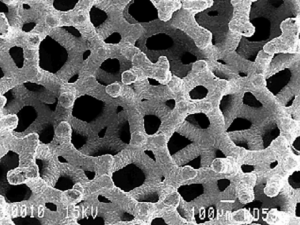

In 1940, pure tantalum metal was first used in medical treatment, and most reports believe that tantalum as a human implant did not find any adverse reactions. The application of tantalum metal mainly focuses on the use of porous tantalum, which is a honeycomb three-dimensional structure with characteristics of the human cancellous bone structure, and the average pore size of which is 430 μm and the porosity is 75%~80%. Porous tantalum can be made into various specifications and shapes. For example, porous tantalum rods can be used for the treatment of early ischemic necrosis of the femoral head; the combination of porous tantalum and human bone is firm, so tantalum can also be used in the preparation of artificial joints; the porous tantalum can also be used as filling material for all parts of the human body, such as tissue reconstruction after tumor resection, dissolving and filling of the neck and lumbar, and vertebral arch replacement.

Stanford Advanced Materials supplies high-quality tantalum and related products to meet our customers’ R&D and production needs. Please visit http://www.samaterials.com for more information.