Introduction

Refractory metals, such as tungsten (W), molybdenum (Mo), and tantalum (Ta), are known for their unique properties, including impressive heat resistance and outstanding strength. This makes them essential for high-temperature propulsion applications.

However, their high melting points and hardness also make them expensive and difficult to manufacture. Additive Manufacturing (AM) is emerging as a promising solution to these challenges. Let’s explore the potential of AM in overcoming these obstacles.

The Need for Refractory Metals

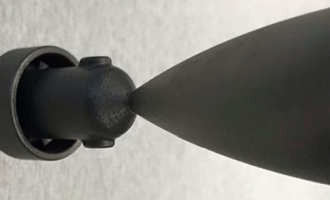

[1]

[1]

Fig. 1 Tungsten Thruster

Refractory metals, such as tungsten (W), molybdenum (Mo), and tantalum (Ta), are crucial in aerospace applications due to their unique properties. These metals are used in a variety of high-stress, high-temperature components, including:

- Reaction Control System (RCS) Thrusters: These are used for precise maneuvering of spacecraft. The extreme temperatures and rapid thermal cycling require materials that can maintain their integrity under such conditions.

- Nuclear Thermal Propulsion (NTP) Fuel Clads: These clads must withstand the intense heat generated during nuclear reactions, making refractory metals indispensable.

- Hypergolic and Green Propulsion Chambers: These propulsion systems, which use hypergolic fuels that ignite spontaneously on contact, operate at very high temperatures, necessitating the use of heat-resistant materials.

Related reading: Refractory Metals & Alloys For Aerospace

Traditional Manufacturing Challenges

Despite their advantageous properties, manufacturing refractory metal components has historically been challenging and costly. The traditional manufacturing process involves several issues:

- Material Waste: Achieving the desired near-net shape is difficult, often resulting in substantial material waste. This is particularly problematic given the high cost of refractory metals.

- Extensive Machining: Due to their hardness and high melting points, refractory metals require extensive machining to achieve the final shape. This process is not only time-consuming but also expensive.

- High Costs: The combination of high material costs, significant waste, and labor-intensive machining leads to very high overall costs for producing refractory metal components.

Advantages of Additive Manufacturing

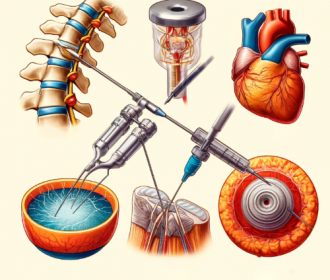

[1]

[1]

Fig 2. Reaction Chambers Made from New Materials

NASA’s Marshall Space Flight Center (MSFC) has been at the forefront of developing AM technologies for producing refractory metal components. Studies have shown that Laser Powder Bed Fusion (L-PBF) AM can significantly reduce the cost and lead time of manufacturing refractory metal parts.

Unlike traditional methods, AM allows for near-net shape production with minimal waste. For instance, the buy-to-fly ratio in traditional manufacturing can be as high as 50:1, whereas AM reduces this ratio to approximately 1.1:1. This substantial reduction in waste not only lowers costs but also makes the process more environmentally friendly.

AM offers several advantages over traditional manufacturing methods:

- Reduced Material Waste: AM allows for near-net shape production, significantly reducing material waste. For example, the buy-to-fly ratio in traditional manufacturing can be as high as 50:1, whereas AM reduces this ratio to approximately 1.1:1.

- Lower Costs: By minimizing waste and reducing the need for extensive machining, AM can lower the overall costs of manufacturing refractory metal components.

- Design Flexibility: AM enables the production of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

Current Challenges and Solutions

Despite its advantages, AM of refractory metals faces several challenges. The high thermal gradients during the AM process can induce residual stresses and micro-cracking, especially in materials with low ductility like tungsten and molybdenum. To address these issues, NASA has been exploring various approaches, including:

- Dispersoid Strengthening: Adding ceramic nano-powders (dispersoids) to the metal matrix during the AM process can refine grain structures, reduce residual stresses, and improve mechanical properties at high temperatures. For example, adding zirconium carbide (ZrC) to tungsten has shown to significantly decrease micro-cracking.

- New Alloy Development: Developing new refractory metal alloys specifically optimized for AM processes can enhance printability and performance. For instance, solid-solution alloys such as W-5Nb and W-7Ni-3Fe have shown improved printability and mechanical properties compared to pure tungsten.

Conclusion

Additive Manufacturing of refractory metals offers significant potential for aerospace applications, providing cost savings, design flexibility, and reduced lead times. While challenges remain, ongoing research and development are paving the way for broader implementation of AM in producing high-performance refractory metal components.

The future of AM in the aerospace industry looks promising, with continued advancements expected to overcome current limitations and unlock new possibilities for high-temperature applications. For more information about refractory metals, please visit Advanced Refractory Metals (ARM).

Reference:

[1] NASA (2021, July 1). Additive Manufacturing of Refractory Metals for Aerospace. Retrieved June 18, 2024, from chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://ntrs.nasa.gov/api/citations/20210018657/downloads/AM_Refrac_(AIAA-2021-3533319)_15Jul2021.pdf

Recent Comments