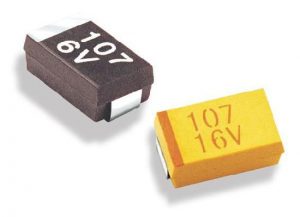

As tantalum capacitors have become more widely used in the market, their models and supply volumes have increased and prices have started to fall. Nowadays, aluminum electrolytic capacitors are replaced by tantalum capacitors in many industries. Of course, tantalum capacitors also have their own defects, such as not having high enough pressure, which greatly limits their use area.

Tantalum is easily oxidized in the air. The tantalum capacitors made by using its oxide film as the medium have the function of repairing wounds automatically, so they are durable and reliable. The tantalum oxide film is very thin, so the distance between two plates of tantalum capacitors is very close, and the reaction is very sensitive, so the charging and discharging speed is fast. These characteristics determine that tantalum capacitors are suitable for high-frequency, low-current, and fast reactive circuits. Therefore, tantalum capacitors are widely used in satellites and other circuits requiring fast response and high reliability.

Tantalum capacitors are often used in advanced audio circuits, mainly high audio circuits, due to their high sensitivity and fast charge-discharge. As the loss of weak current to high audio is reduced, the relatively high pitch and sound quality are improved. In short, the tantalum capacitive microphone has the following advantages.

Broad frequency response

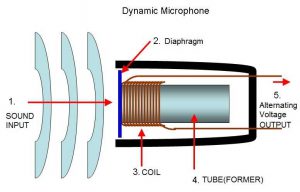

The vibrating membrane is the main component of the microphone which induces sound and converts it into an electrical signal, and the material and mechanism design of the vibrating film is an important factor to determine the sound quality of the microphone. The vibrating membrane of a capacitive microphone can be made of extremely thin material and the induced sound pressure is converted directly into an audio signal, so the bass of frequency response can extend to the ultra-low frequency below 10Hz, and the high tone can easily reach the ultrasonic waves of dozens of KHz, showing very broad frequency response characteristics.

Hypersensitivity

Because there is no load on the diaphragm, the diaphragm can be designed in such a light and thin way that the frequency response is superior and the sensitivity is excellent. It can sense extremely weak sound waves, and output the clearest, most delicate, and most accurate original sound.

Fast transient response

In addition to the characteristics that determine the frequency response and sensitivity of the microphone, the ability of the vibrating membrane to react quickly to sound waves, namely the “instantaneous response” characteristic, is one of the most important factors that affect the microphone’s timbre. The speed of the instantaneous response of the microphone depends on the weight of the whole vibrating membrane. The lighter the vibrating membrane, the faster the reaction speed. The extremely thin vibrating film of the capacitive voice head has an extremely fast transient response, so it can show a clear, energetic, and accurate timbre.

Resistance to fall and impact

In general, the use of microphones can be caused by accidental falls and collisions. Since the capacitive head is made up of lighter plastic parts and a sturdy light metal case, the impact force on the falling ground is small and the failure rate of damage is low.

Small size and lightweight

The capacitive microphone has the advantages of small volume, lightweight, high sensitivity, and superior frequency response due to its ultra-thin vibrating membrane, so it can be designed into subminiature microphones (commonly known as small bees and small ants) and is widely used.

Please visit http://www.samaterials.com for more information.

Recent Comments