Capacitor grade tantalum wire is specifically designed to meet the stringent requirements of the electronics industry, offering superior electrical conductivity, corrosion resistance, and chemical stability. This article delves into the properties, manufacturing process, and applications of capacitor grade tantalum wire, highlighting its importance in modern technology.

Properties of Capacitor Grade Tantalum Wire

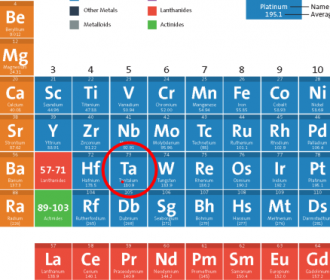

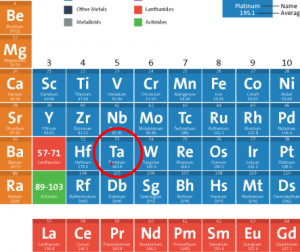

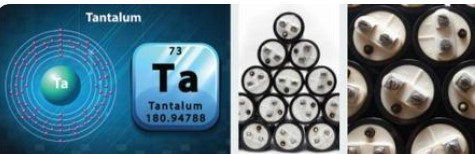

Tantalum, a rare and highly corrosion-resistant metal, exhibits a unique set of properties that make it ideal for use in electronic components such as capacitors. The key properties of capacitor grade tantalum wire include:

- High Purity:

Capacitor grade tantalum wire is manufactured with extremely high purity levels (often exceeding 99.95%) to ensure optimal performance in electronic applications.

- Excellent Corrosion Resistance:

Tantalum’s ability to resist oxidation and corrosion, even in highly reactive environments, ensures the longevity and reliability of capacitors.

- Superior Conductivity:

The wire offers excellent electrical conductivity, allowing it to serve as an effective lead or anode connection in capacitors.

- Thermal Stability:

Tantalum maintains its structural integrity and performance across a wide range of temperatures, making it ideal for use in demanding environments.

- Biocompatibility:

In addition to its electrical applications, tantalum’s biocompatibility has made it suitable for medical-grade capacitors used in implantable devices.

Manufacturing Process of Capacitor Grade Tantalum Wire

The production of capacitor grade tantalum wire involves a precise and controlled process to ensure high purity and optimal performance. The main steps include:

- Raw Material Processing:

Tantalum ore, primarily extracted as tantalum pentoxide (Ta₂O₅), is refined through a series of chemical processes to remove impurities. The refined tantalum is then converted into a powder or ingot form.

- Melting and Casting:

The refined tantalum is melted in a vacuum or inert gas environment to create high-purity ingots. These ingots form the basis for wire production.

Electron beam melting or vacuum arc remelting techniques are commonly used to achieve the necessary purity levels.

- Wire Drawing:

The tantalum ingot is forged into rods and then drawn into wires of the desired diameter through successive stages of extrusion and drawing.

Each step is carefully controlled to ensure uniformity and precision.

- Annealing:

The wire is annealed at high temperatures to relieve internal stresses and improve its ductility, which is crucial for its use in capacitor manufacturing.

- Surface Treatment:

To achieve the desired surface finish and prevent contamination, the wire undergoes cleaning and polishing processes.

Applications of Capacitor Grade Tantalum Wire

1. Tantalum Capacitors:

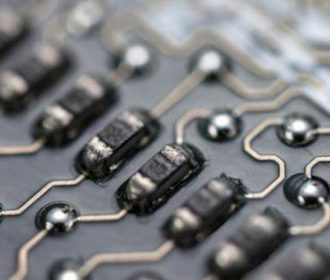

The primary application of capacitor grade tantalum wire is in the manufacturing of tantalum capacitors. These capacitors are widely used in electronic devices due to their compact size, high capacitance, and reliability. The wire serves as a lead or anode connection, providing a crucial pathway for electrical conductivity.

- Consumer Electronics: Tantalum capacitors are integral to smartphones, laptops, gaming consoles, and wearable devices.

- Automotive Industry: Used in automotive electronic control units (ECUs), sensors, and infotainment systems.

- Telecommunications: Essential for high-frequency applications in base stations, network routers, and satellite communications.

2. Medical Devices:

Tantalum wire is used in medical-grade capacitors for implantable devices like pacemakers, defibrillators, and hearing aids due to its biocompatibility and reliability.

3. Aerospace and Defense:

Capacitor grade tantalum wire is employed in avionics, missile systems, and space equipment, where high reliability and resistance to extreme conditions are critical.

4. Industrial Applications:

In industrial equipment, tantalum capacitors with high-grade wires are used in power supplies, motor drives, and energy storage systems.

Advantages of Tantalum Wire in Capacitors

The use of tantalum wire in capacitors offers several advantages over other materials, including:

- High Capacitance-to-Volume Ratio:

Tantalum capacitors, enabled by tantalum wire, can store more charge per unit volume compared to other types, making them ideal for compact devices.

- Long Lifespan:

The corrosion resistance and thermal stability of tantalum wire contribute to the extended operational life of capacitors.

- Stable Performance:

Tantalum capacitors exhibit stable performance across a wide range of temperatures and frequencies, thanks to the properties of tantalum wire.

- Reliability in Extreme Environments:

The wire’s resistance to oxidation and chemical attack makes it suitable for aerospace and military applications.

Conclusion

Capacitor grade tantalum wire is a cornerstone material in the electronics industry, enabling the production of reliable, compact, and efficient tantalum capacitors. Its exceptional properties, including high purity, corrosion resistance, and thermal stability, make it indispensable in consumer electronics, medical devices, aerospace, and industrial applications. For more information, please visit Advanced Refractory Metals (ARM).

Recent Comments