As a new manufacturing method for the global manufacturing industry, additive manufacturing caught the attention of the public six or seven years ago. And “3D printing”, a very down-to-earth and vivid name, was coined. Metal 3D printing is widely regarded as the most promising technology. Tantalum powder is an excellent biocompatible material, which has very strong biological inertia and corrosion resistance. Stanford Advanced Materials (SAM) has begun research on the application of 3D printing of tantalum powder in biomedicines such as hip joints.

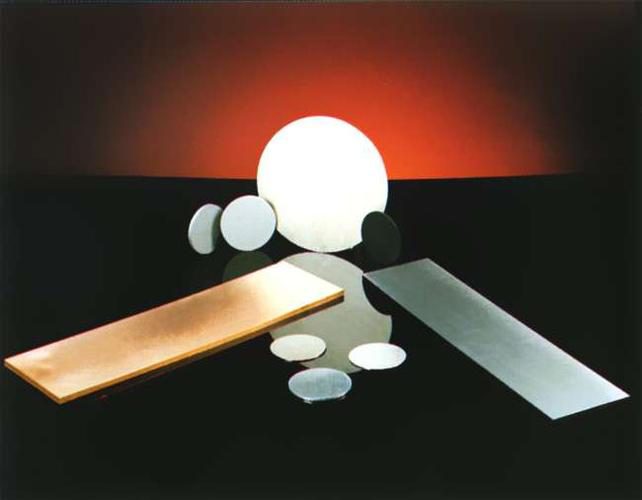

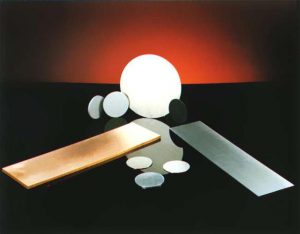

Tantalum has a high boiling point, excellent resistance to corrosion, low coefficient of thermal expansion, and a high coefficient of capacitance, which has been used in electronic industries. SAM’s spherical tantalum powder is a good choice for 3d printing tech as it has high purity, uniform particle size, complete surface structure, easy dispersion, large specific surface area, and high surface activity.

SAM has successfully produced a biologically inert tantalum lattice structure and can have specific and random results. These structures follow the structural rigidity of human bones and can be well combined with bone cells so that the human body can excellently accept this kind of new tissue. SAM is dedicated to providing ultra-fine tantalum powder (D50=3um, D90<10um) for bio-applications. When used for additive manufacturing and selective laser melting, this type of ultra-fine tantalum powder can always maintain structural consistency. The final surface can also be further modified. The metal properties are still very stable.

SAM has successfully produced a biologically inert tantalum lattice structure and can have specific and random results. These structures follow the structural rigidity of human bones and can be well combined with bone cells so that the human body can excellently accept this kind of new tissue. SAM is dedicated to providing ultra-fine tantalum powder for bio-applications. When used for additive manufacturing and selective laser melting, this type of ultra-fine tantalum powder can always maintain structural consistency. The final surface can also be further modified. The metal properties are still very stable.

Please visit http://www.samaterials.com for more information.