Introduction

Superalloys are high-performance materials made to withstand extreme conditions like high temperatures, mechanical stress, and corrosive environments. They are crucial in industries where durability and reliability are vital, such as aerospace, power generation, and chemical processing. The main types of superalloys are nickel-based, cobalt-based, iron-based, and titanium-based alloys. Each group has unique properties for specific industrial needs.

1. Nickel-Based Superalloys

Nickel-based superalloys are known for their strength and resistance to oxidation and corrosion at high temperatures.

- Inconel 718: This is one of the most widely used nickel-based superalloys. It is used in jet engines, gas turbines, and nuclear reactors because it retains its strength at high temperatures.

- Inconel 625: This alloy is favored in marine and chemical processing applications for its excellent corrosion resistance and thermal stability.

- Hastelloy X: Known for its outstanding oxidation resistance and ease of fabrication, this alloy is commonly used in gas turbine engines and industrial furnaces.

- Waspaloy: This alloy is essential for aerospace engine components due to its high-temperature strength and oxidation resistance.

Related reading: 4 Types Of Superalloys You May Want To Know

2. Cobalt-Based Superalloys

Cobalt-based superalloys offer high-temperature strength and superior wear resistance, making them ideal for demanding applications.

- Haynes 188: Extensively used in gas turbine engines and combustor liners, this alloy maintains its strength and resists oxidation at high temperatures.

- Stellite 6B: Known for its exceptional wear resistance, this alloy is commonly used for valve seats, cutting tools, and bearing surfaces.

- Tribaloy T-400: This alloy is used in high-temperature bearings and wear-resistant applications due to its excellent wear and corrosion resistance.

- MAR-M 509: This alloy is used in turbine blades, vanes, and combustor parts because of its high-temperature stability.

3. Iron-Based Superalloys

Iron-based superalloys are often used where a combination of strength and corrosion resistance is needed.

- A-286: This common iron-based superalloy is used in jet engine components, fasteners, and springs due to its high strength and good oxidation resistance.

- Incoloy 800: Known for its resistance to oxidation and carburization, this alloy is widely used in heat exchangers, nuclear power plants, and chemical processing.

- Hastelloy D-205: This alloy is used in high-temperature industrial applications and furnace parts due to its excellent resistance to thermal fatigue and oxidation.

4. Titanium-Based Superalloys

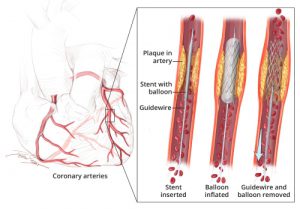

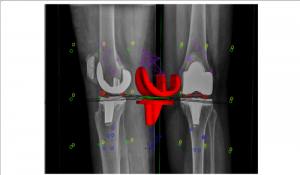

Titanium-based superalloys are celebrated for their high strength-to-weight ratio and corrosion resistance, making them ideal for aerospace and biomedical applications.

- Ti-6Al-4V (Grade 5): This is the most commonly used titanium alloy. It is extensively employed in aerospace components, biomedical implants, and marine applications due to its excellent combination of strength, light weight, and biocompatibility.

- Ti-6242: Known for its high-temperature stability and strength, this alloy is used in jet engine components and gas turbines, where it can withstand extreme operating conditions.

| Superalloy Type | Alloy | Key Properties | Applications |

| Nickel-Based | Inconel 718 | Exceptional strength,

oxidation and corrosion resistance |

Jet engines,

gas turbines, nuclear reactors |

| Inconel 625 | Remarkable corrosion

resistance, thermal stability |

Marine applications, chemical processing | |

| Hastelloy X | Outstanding oxidation

resistance, fabricability |

Gas turbine engines, industrial furnaces | |

| Waspaloy | High-temperature

strength, oxidation resistance |

Aerospace engine components | |

| Cobalt-Based | Haynes 188 | High-temperature strength, oxidation resistance | Gas turbine engines, combustor liners |

| Stellite 6B | Exceptional

wear resistance |

Valve seats,

cutting tools, bearing surfaces |

|

| Tribaloy T-400 | Excellent wear

and corrosion resistance |

High-temperature

bearings, wear-resistant applications |

|

| MAR-M 509 | High-temperature stability | Turbine blades,

vanes, combustor parts |

|

| Iron-Based | A-286 | High strength, good

oxidation resistance |

Jet engine components,

fasteners, springs |

| Incoloy 800 | Resistance to oxidation

and carburization |

Heat exchangers,

nuclear power plants, chemical processing |

|

| Hastelloy D-205 | Excellent resistance

to thermal fatigue and oxidation |

High-temperature

industrial applications, furnace parts |

|

| Titanium-Based | Ti-6Al-4V (Grade 5) | High strength-to-weight

ratio, corrosion resistance, biocompatibility |

Aerospace components, biomedical implants,

marine applications |

| Ti-6242 | High-temperature

stability, strength |

Jet engine components,

gas turbines |

In addition to these primary categories, there are other notable superalloys that cater to specific needs.

Tungsten-based superalloys are used in aerospace and defense applications due to their high density and excellent radiation shielding properties. Rhenium-based superalloys are employed in high-temperature turbine blades and rocket engines because of their exceptional high-temperature strength and creep resistance.

Conclusion

Superalloys include nickel-based, cobalt-based, iron-based, and titanium-based alloys. They are crucial for advanced engineering and manufacturing. Nickel-based superalloys are valued for their strength and heat resistance. Cobalt-based superalloys excel in resisting wear and staying stable at high temperatures. Iron-based superalloys offer a good mix of strength and corrosion resistance. Titanium-based superalloys are strong, lightweight, and biocompatible.

Understanding the unique properties and applications of these superalloys is essential for optimizing their use in various industrial applications, ensuring reliability and performance in demanding conditions. For more details, please check Advanced Refractory Metals (ARM).

[1]

[1] [2]

[2]

[1]

[1] [1]

[1]

Recent Comments