Data and Market

Niobium, a shiny, white, ductile metal with the atomic number 41, is a crucial element in modern steel production. It is primarily sourced from the minerals pyrochlore and columbite, with Brazil being the leading producer, contributing approximately 90% of the global supply. The global niobium market was valued at around USD 2 billion in 2023, with expectations to grow significantly due to increasing demand in steel manufacturing, electronics, and other high-tech industries.

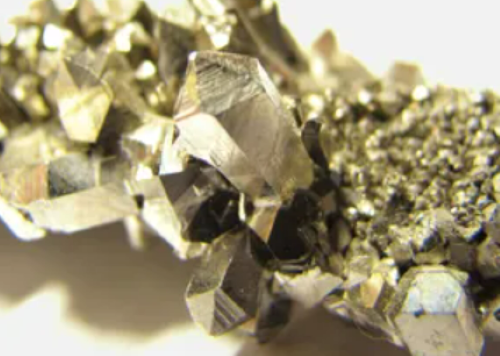

[1]

[1]

The steel industry consumes the majority of niobium (Nb), utilizing it primarily as a microalloying element. This use accounts for approximately 80% of Nb production. The remaining 20% is used in superconducting materials, superalloys, and other advanced applications. The demand for Nb is closely linked to the growth of the steel industry, which is projected to grow at a CAGR of 3-4% over the next decade.

Mechanism

Niobium is added to steel in small amounts, typically between 0.01% and 0.1%, during the steelmaking process. Despite the small quantities used, it plays a significant role in enhancing the properties of steel. The primary mechanism through which niobium improves steel is through grain refinement. When added to molten steel, niobium forms niobium carbides and nitrides, which inhibit the growth of grains during the cooling process.

Grain refinement enhances the strength, toughness, and weldability of steel. Niobium also contributes to the precipitation hardening of steel, where fine niobium carbides precipitate within the steel matrix, further enhancing its strength. Additionally, Nb helps in controlling the transformation of austenite to ferrite during cooling, which improves the steel’s overall mechanical properties.

Benefits

The inclusion of Nb in steel production offers several notable benefits:

- Increased Strength and Toughness: Nb enhances the yield and tensile strength of steel, allowing for the production of high-strength, low-alloy (HSLA) steels. These steels are essential in applications requiring both strength and toughness, such as the automotive and construction industries.

- Improved Weldability: Niobium-containing steels exhibit better weldability compared to traditional steels. This is crucial for construction projects and automotive manufacturing, where strong and reliable welds are essential.

- Enhanced Corrosion Resistance: Niobium improves the corrosion resistance of steel, making it suitable for use in harsh environments, such as offshore platforms and chemical processing plants.

- Weight Reduction: By enabling high-strength steel production, Nb allows for weight reduction in various applications. This is particularly beneficial in the automotive and aerospace industries, where reducing weight can lead to improved fuel efficiency and performance.

Applications

Niobium-containing steels find application across a wide range of industries due to their superior properties:

- Construction: In the construction industry, niobium-containing steels are used in the manufacturing of high-strength structural components, such as beams and columns. These materials provide the necessary strength and durability required for modern infrastructure projects.

- Automotive: The automotive industry uses niobium-alloyed steel to produce lightweight yet strong vehicle components, including chassis, body panels, and safety structures. This contributes to improved fuel efficiency and safety in vehicles.

- Energy: Niobium-containing steels are employed in the energy sector to construct pipelines, pressure vessels, and storage tanks. Their high strength and corrosion resistance make them ideal for handling the demanding conditions of the oil, gas, and petrochemical industries.

- Aerospace: The aerospace industry benefits from niobium-enhanced steels in the production of landing gear, engine components, and structural parts. The combination of high strength and lightweight properties is critical for the performance and safety of aircraft.

- Shipbuilding: In shipbuilding, niobium-containing steel is used to construct hulls, decks, and other structural components. The enhanced strength and corrosion resistance of niobium-containing steels contribute to the longevity and reliability of ships operating in marine environments.

Related reading: 10 Important Uses of Niobium

Conclusion

Niobium plays a pivotal role in modern steel production, offering increased strength, improved weldability, enhanced corrosion resistance, and weight reduction. Its ability to significantly improve the mechanical properties of steel while being used in relatively small quantities makes it an invaluable element in steel production.

As global demand for high-performance materials continues to grow, Nb’s importance in steel production and other advanced applications is set to rise, driving further innovations and developments in material science and engineering. For more Niobium products, please check Advanced Refractory Metals (ARM).

Reference:

[1] Niobium. (2024, August 6). In Britannica. https://www.britannica.com/science/niobium