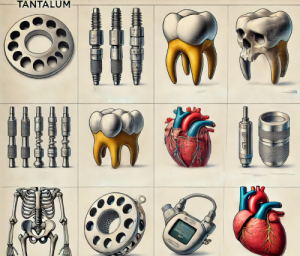

Introduction

Tantalum, a rare and highly versatile metal, has become increasingly prominent in the field of medicine due to its unique properties. Known for its excellent corrosion resistance, high melting point, and biocompatibility, tantalum is widely used in various medical applications. Here, we explore eight common uses of tantalum in medicine and how this remarkable metal contributes to advancements in healthcare.

1. Orthopedic Implants

One of the most significant applications of tantalum is in orthopedic implants. Tantalum’s biocompatibility and ability to integrate seamlessly with bone tissue make it an ideal material for hip and knee replacements, spinal implants, and bone grafts. The porous structure of tantalum implants allows for bone in-growth, enhancing the stability and longevity of the implants. This has led to improved outcomes for patients undergoing joint replacement surgeries and other orthopedic procedures.

2. Dental Implants

Tantalum is also used in dental prosthetics and implants. Its corrosion resistance and biocompatibility make it suitable for long-term use in the oral environment. These dental implants provide a stable foundation for replacement teeth, ensuring durability and functionality. This application has revolutionized dental care, offering patients reliable solutions for tooth loss.

3. Surgical Instruments

The durability and resistance to corrosion of tantalum make it an excellent material for manufacturing surgical instruments. Such scalpels, forceps, and other tools can withstand the rigors of repeated sterilization and use, maintaining their sharpness and effectiveness over time. This reliability is crucial for surgical precision and patient safety.

4. Radiopaque Marker Bands

Tantalum marker bands play a vital role in medical imaging. These radiopaque bands are used to visualize the position of medical devices such as catheters and stents during procedures. Ta’s high density makes it easily visible under X-rays and other imaging techniques, aiding doctors in accurately placing and monitoring these devices. This application is essential for minimally invasive surgeries and interventional radiology.

5. Vascular Stents

In cardiovascular medicine, Ta is used in the construction of vascular stents. These small mesh tubes are inserted into blood vessels to keep them open, ensuring proper blood flow. Tantalum capillaries and stents are non-reactive and biocompatible, reducing the risk of adverse reactions and improving patient outcomes. Additionally, their radiopacity allows for easy monitoring and adjustment if necessary.

6. Cranioplasty

Tantalum plates are employed in cranioplasty, a surgical procedure to repair defects or deformities in the skull. These plates provide the necessary strength and stability while promoting bone growth. The use in cranioplasty has improved the success rates of reconstructive surgeries, offering patients better protection and aesthetic outcomes.

7. Pacemaker Cases

Ta’s stability and compatibility with body tissues make it an ideal material for the casings of pacemakers and other implantable electronic devices. These devices require materials that can withstand long-term implantation without degrading or causing adverse reactions.

8. Radiation Shielding

In radiotherapy, tantalum is used in shielding devices to protect sensitive tissues and organs from radiation exposure. Its high density and ability to absorb radiation make it an effective material for this purpose. Tantalum shields help minimize the side effects of radiation therapy, improving patient comfort and outcomes during cancer treatments.

Conclusion

Tantalum is a vital material in medicine due to its strength, resistance to corrosion, and biocompatibility. It is used in many applications, from implants and surgical tools to imaging aids and radiation protection. As medical technology advances, the use of tantalum will continue to grow, helping to improve patient care and outcomes. For more tantalum products, please check Advanced Refractory Metals (ARM).

Recent Comments