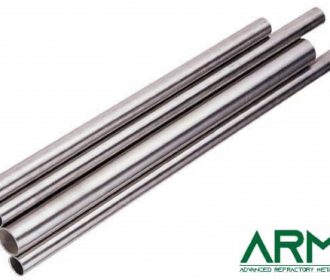

Tantalum is a highly specialized material known for its exceptional biocompatibility, corrosion resistance, and high-temperature stability, making it indispensable in advanced medical and biomedical applications. When formed into capillaries—thin, tube-like structures—tantalum offers a reliable and durable solution for a range of medical devices and procedures. The unique properties of tantalum capillaries make them a go-to material in applications requiring precise fluid handling, resistance to bodily fluids, and the ability to perform under extreme conditions.

1. Biocompatibility for Safe Medical Use

Tantalum is widely regarded for its outstanding biocompatibility, meaning it does not elicit an adverse reaction when implanted or used in contact with human tissues. This makes tantalum capillaries an ideal choice for use in biomedical devices, where material safety is a priority. Tantalum’s ability to resist corrosion from bodily fluids such as blood, saliva, and other bodily excretions ensures long-term stability and minimizes the risk of rejection or infection.

- Example: Tantalum capillaries are used in implantable devices like pacemakers, where the material ensures that no harmful substances leach into the body over time.

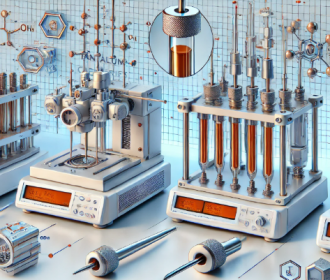

2. Fluid Transport in Medical Devices

Tantalum capillaries are critical components in medical devices that require the transport of fluids—whether for diagnostic purposes, drug delivery, or other medical functions. Their small diameter and resistance to clogging and corrosion make them suitable for delivering precise amounts of fluids in intricate devices such as infusion pumps, catheter systems, and drug delivery systems.

- Example: In drug infusion systems, tantalum capillaries help regulate the flow of medication with accuracy, ensuring that patients receive the correct dosage without interference from material degradation.

3. Radiation Resistance in Imaging Equipment

Another important application of tantalum capillaries in the medical field is in medical imaging systems. Tantalum’s high density and radiation-shielding properties make it suitable for use in systems like X-ray machines, CT scanners, and radiation therapy devices. Tantalum capillaries help improve the precision and effectiveness of these devices, ensuring that radiation exposure is controlled, and medical personnel and patients are shielded from unnecessary radiation.

- Example: In imaging systems, tantalum capillaries can be used to guide precise beams of radiation, or to protect sensitive areas from excessive exposure, while ensuring the accuracy of the imaging process.

4. Durability in High-Temperature Environments

Many medical devices operate in environments where high temperatures are encountered, either during sterilization processes or within the operating body, such as in deep tissue implants or devices used in thermotherapy. Tantalum capillaries are resistant to thermal stress, maintaining their structural integrity even under elevated temperatures. This makes them ideal for devices requiring durability under harsh sterilization conditions.

- Example: Tantalum capillaries are used in surgical robots and other high-precision instruments, where they need to withstand extreme sterilization conditions while maintaining performance.

5. Applications in Implantable Medical Devices

Tantalum’s high strength and inertness make it particularly useful for implantable devices, such as those used in orthopedic surgery, neurology, and cardiovascular procedures. Tantalum capillaries are used in a variety of implantable devices that require fluid handling or controlled delivery of substances, such as in the case of stents, pacemakers, or biosensors. These implants must endure long-term exposure to the human body without failure, and tantalum provides the necessary resilience.

- Example: Tantalum capillaries are incorporated into pacemakers for the controlled release of energy, ensuring reliable functioning for extended periods.

6. Precision in Medical Instruments

Tantalum capillaries also play a key role in enhancing the precision and functionality of high-end medical instruments. Their use in diagnostic equipment, laboratory devices, and surgical tools helps achieve accuracy in measurements and fluid handling. Tantalum’s properties allow for the manufacturing of capillaries with extremely fine diameters, ideal for precision applications where minute adjustments are critical.

- Example: In diagnostic instruments like blood analyzers, tantalum capillaries are used to transport very small volumes of fluid, ensuring accurate test results.

7. Long-Term Reliability and Low Maintenance

Given that tantalum is highly resistant to wear, corrosion, and chemical attack, devices featuring tantalum capillaries require less maintenance and offer long-term reliability. This is particularly important in medical and biomedical fields where device failure can have serious consequences. By using tantalum, manufacturers can ensure that devices maintain peak performance over extended periods.

- Example: Tantalum capillaries are used in insulin pumps, where consistent performance and long-term reliability are critical for managing diabetes.

Conclusion

Tantalum capillaries are an essential material in the development of advanced medical and biomedical devices, offering a unique combination of biocompatibility, durability, and precision. From implantable devices and medical imaging systems to diagnostic tools and fluid delivery mechanisms, tantalum capillaries are helping improve the safety, efficiency, and performance of critical medical technologies. With continued advancements in medical technology, the role of tantalum capillaries will likely expand, driving innovations that improve patient care and outcomes. For more information, please check Advanced Refractory Metals (ARM).

Recent Comments