The inner covering of the gun body

When gunpowder is exploded, it produces a tail flame with a temperature of 2500 ~ 3500K and a pressure of 300 ~ 800MPa. The tail flame contains such corrosive components as H2S, CO, O2, H2, H2O, N2, and powder residue particles. Therefore, the gun barrel will undergo the physical and chemical effects of high-temperature and high-pressure gunpowder gas (the thermal effect of high-temperature gas, the scouring of high-speed airflow, the corrosion of gunpowder gas residue in the bore, and the wear of high-speed moving projectile on the inner wall) when the projectile is launched. Under this working condition, the gun barrel bore will be subjected to severe ablative erosion and wear, which will lead to the change in the geometry and size of the barrel bore, which will directly affect the firing accuracy of the gun and the life of the barrel.

Therefore, the research on ablative behavior and protection of gun barrels has received extensive attention. The main considerations of gun barrel material are thermal properties, including heat resistance, thermal expansion, thermal conductivity, and thermal shock resistance; mechanical properties, including elastic modulus, mechanical strength, and hardness; chemical stability, that is, the chemical stability of materials in high temperature and corrosive atmosphere.

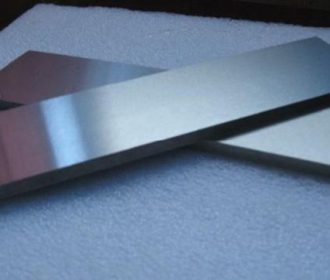

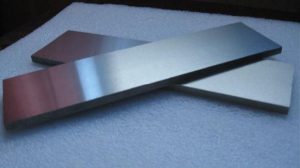

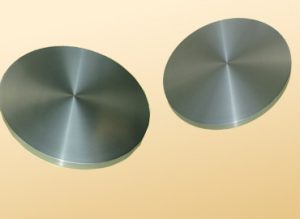

Tantalum (Ta) has good physical and chemical properties. It is a high melting point (2996℃) refractory metal, with low thermal conductivity (57W/m℃), good chemical corrosion resistance (acid, salt, and organic chemical corrosion resistance at high temperature), and excellent ablative resistance, as well as good plastic and toughness. Tantalum or tantalum alloy coating is considered to be an ideal coating system to replace the electroplating Cr coating for ablative and scour resistance. If the tantalum layer is to be used in the gun barrel for the purpose of gas ablation of fire retardant for a long time, the sputtering Ta layer should be mainly composed of alpha-ta with a thickness of at least 75 microns. The coating should have enough binding force with the substrate in all directions to resist the thermal shock and high shear stress in the gun firing process.

The cylindrical magnetron sputtering tantalum technology was proposed by Benet Laboratories of the United States army for the dimension characteristics of the gun barrel; Also, the trial production of cylindrical magnetron sputtering deposition technology platform for 120mm, 155mm, and 105mm sputtering full-length large-caliber gun tubes were built in Waterfleet Arsenal, which was used for the magnetron sputtering full-bore tantalum plating for Abrams, Crusader, and future combat systems.

In the Bennett experiment of the US army, Vigilante et al. prepared pure tantalum ablative resistant layer in a 25mm rifled gun barrel and 120mm smooth rifled gun barrel bore by using explosive spraying technology. It was found that the bonding between the tantalum layer and the base metal was good, but the adiabatic shear band would appear in the base steel of the body tube and a Ta-Fe brittle intermetallic compound phase would be formed.

Armor-piercing projectile

In the 1980s, a new type of warhead, the explosively formed penetrator, was successfully developed, mainly using tantalum on the butterfly bushing next to the high explosive. When the explosive is detonated, the butterfly disc morphs into a long, steady, sliver of a penetrator, accelerating towards its target.

With the development of armor materials, modern anti-armor warhead has higher and higher requirements on the materials of explosive forming munition type hood. The formation of a longer and more stable jet requires high density, high sound velocity, good thermal conductivity, and high dynamic fracture elongation. In addition, it is required that the material has a fine grain, low recrystallization temperature, certain texture, and other microstructure.

Tantalum and depleted uranium have high density, high dynamic elongation, and arson. Especially, tantalum has a high density (16.6g/cm3) and good dynamic characteristics, which is a kind of material mainly used in the research of explosive forming ammunition types. As a material of explosively formed munitions, tantalum is widely used in TOW-2B, TOW-NG, and other U.S. missiles. Ballistic experiments show that tantalum’s affinity is 30%~35% higher than that of copper, and can reach 150mm.

At present, the research on using tantalum as the coating material mainly focuses on improving the processing technology and saving the cost. Among them, the United States Army Equipment Research and Development Center (ARDEC) uses the P/M method to develop explosively formed tantalum cartridge type housing; Two kinds of tantalum powders, PM2 and PM4, are pressed by static pressure, sintered, extruded, and processed into blank material, and then annealed and forged by rotary forging, tantalum cartridge prepared in this way can be successfully applied to a well-shaped explosive forming projectile; German Smart-155mm end-sensitive projectile is one of the most advanced end-sensitive projectiles in the world today. The missile is made of a thin-wall structure, and its sensitive device has high anti-interference ability, which can work normally in fog or a bad environment; The BONUS-155mm dexterous shell, jointly developed by the Swedish Bofors Company and the ground weapon group, has been mass-produced and is suitable for 45-caliber artillery.

High purity materials are required for the electrochemical cover of explosive forming. Trace elements have a great influence on the physical properties of the cover material, and ultimately affect the penetration depth of the projectile. The purity of tantalum has an influence on the strength, crystal structure, and length of the explosive forming projectile (EFP). Therefore, the purity of tantalum shall be strictly controlled in the preparation process.

Ultra-high vacuum aspirating material

Ultra-high vacuum aspirating material (tantalum alloy) is used in night vision equipment in conventional defense weapons. Using 15% tantalum as the framework and titanium as the adsorbent of hydrogen, oxygen, nitrogen, carbon monoxide, carbon dioxide, water vapor, methane, neon, and other gases can improve the service life of the inspiratory material. This material can be applied to the infrared camera tube in the active infrared night-vision instrument and the low-light tube in the passive low-light night vision instrument, to ensure the long-term high vacuum in the vacuum tube, so as to achieve the high efficiency, high-life span and improve the definition of the night vision instrument.

Stanford Advanced Materials supplies high-quality tantalum products to meet our customers’ R&D and production needs. Please visit https://www.samaterials.com for more information.

Recent Comments