Rare metal material technology is one of the most important subjects in the field of material science and engineering in the new century, as well as a key material for the development of high and new technology, and tantalum and niobium play an important role in this field. The development of modern high technology such as information technology, new energy technology, space technology, biotechnology, and superconductivity is closely related to rare metal materials, especially tantalum and niobium.

Main products and performance

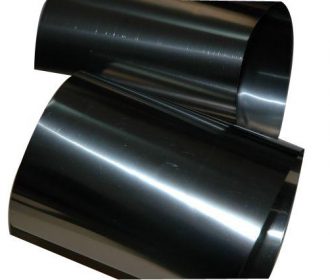

At present, the main products used in the tantalum-niobium industry include tantalum powder, tantalum wire, tantalum carbide, tantalum, and its alloy ingots, tantalum and its alloy processing materials, tantalum target materials, tantalum oxide, lithium tantalite; niobium powder, niobium rod, niobium foil, and its alloy ingots, niobium and its alloy additives, niobium oxide, niobium tube, lithium niobate, niobium, and its alloy superconducting materials, etc.

Tantalum powder and tantalum wire are the key materials for making tantalum capacitors, which are widely used in mobile phones, computers, digital products, automobiles, aerospace electronics, and other fields. About 60 percent of the world’s tantalum is used to make tantalum capacitors.

Tantalum and niobium target materials are used in semiconductor devices and liquid crystal display technologies, and niobium oxide, niobium powder, and niobium wire are used in making ceramic and niobium capacitors. About 90% of the world’s niobium is used in the steel industry, and niobium wire is mainly used in the production of high-strength low-alloy steel, stainless steel, heat-resistant steel, clearance steel, carbon steel, tool steel, rail steel, casting steel.

Superalloys can be produced by adding tantalum or niobium to tungsten, molybdenum, nickel, cobalt, vanadium, ferroalloys, or by using tantalum and niobium as bases, which are important structural materials for aerospace engines, ground-based air turbine engines, modern weapons, and harsh industrial environment facilities.

Because of the good superconductivity of niobium and tantalum metal, the addition of niobium and tantalum into the materials used to make wires and cables can greatly reduce the loss of power and thus save power. Tantalum and niobium are excellent materials for acid and liquid metal corrosion resistance, so they can be used in the chemical industry for digesters, heaters, coolers, and various device containers. Besides that, tantalum and niobium metals and their alloys can also be used as reactor shell materials and high-energy physics superconducting devices.

Industry’s outlook

With the development of high and new technology in the world, such as electronics, metallurgy, aerospace, and aviation, the international market demands for the smelting and processing of rare metals such as tantalum powder and tantalum wire, tantalum niobium crystal materials and niobium alloy are increasing day by day. Currently, major tantalum and niobium metal smelters and processing industries around the world are carrying out global economic integration, and actively exploring the market to improve the market share.

Stanford Advanced Materials supplies high-quality tantalum and niobium products to meet our customers’ R&D and production needs. Please visit http://www.samaterials.com for more information.

Recent Comments