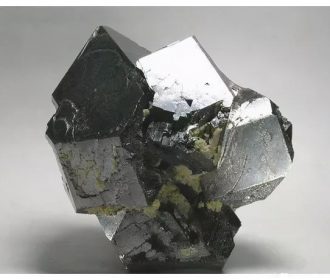

Tantalum ribbon is a dark blue-gray metallic material that stands out for its exceptional properties, including high corrosion resistance, ductility, and hardness. Known for its ability to perform in extreme conditions, it is widely used across industries such as electronics, aerospace, medical devices, and chemical processing. This article explores these properties, applications, and advantages.

Key Properties of Tantalum Ribbon

- Corrosion Resistance:

Tantalum is highly resistant to most chemicals, including acids, at temperatures below 150 °C. It can only be dissolved by hydrofluoric acid, making it ideal for harsh chemical environments. - High Melting Point:

With the fourth-highest melting point of all metals (3,017°C or 5,463°F), Ta ribbon excels in high-temperature applications. - Ductility and Hardness:

Ta ribbon is both ductile and hard, allowing it to be processed into ultra-thin formats without losing strength, making it suitable for precise engineering. - Oxide Layer Formation:

Tantalum naturally forms a thin, stable oxide layer, providing excellent protection and ensuring its suitability for high-quality capacitors and other electronic components. - Vacuum Compatibility:

Ta ribbon absorbs hydrogen, oxygen, and nitrogen from the atmosphere, making it especially effective in vacuum environments. This property is valuable in the lighting industry and thin-film deposition processes.

Applications of Tantalum Ribbon

- Electronics

Ta ribbon’s ability to form a protective oxide layer makes it a key material in the production of capacitors and resistors. These components are critical in electronic devices, including smartphones, laptops, and industrial equipment. Its stability and conductivity ensure consistent performance and longevity. - Chemical Processing

Due to its resistance to corrosion, ta ribbon is used to line reactors, heat exchangers, and vessels that handle highly corrosive chemicals. This enhances the durability of chemical processing equipment and minimizes downtime caused by material degradation. - Medical Devices

Ta’s biocompatibility makes it a preferred material for surgical implants, such as bone replacements and pacemakers. Its non-reactive nature ensures safety and durability when used in medical environments, while its ductility allows it to be formed into precise shapes. - Aerospace Applications

Ta ribbon is used in aerospace components subjected to extreme temperatures and mechanical stress. Its high melting point and strength make it ideal for use in jet engines, thermal shields, and other critical systems requiring high performance under harsh conditions. - Lighting Industry

In vacuum applications, Ta ribbon is particularly valuable due to its ability to absorb atmospheric gases like hydrogen and oxygen. This property makes it an essential material for lighting components, including filaments and supports in specialized lamps. - Energy and Renewable Systems

It is increasingly used in advanced energy systems, such as hydrogen fuel cells and batteries. Its conductivity and resistance to wear make it a reliable material in technologies striving for efficiency and sustainability. - Thin-Film Deposition

In the semiconductor and coating industries, It is utilized in thin-film deposition processes. Its properties enable the creation of high-quality films for electronics, optics, and protective layers.

Why Tantalum Ribbon is a Superior Material

- Durability: Exceptional resistance to corrosion, heat, and mechanical wear.

- Versatility: Suitable for diverse applications across multiple industries.

- Reliability: Forms protective oxide layers that enhance performance in critical systems.

- Customizability: Available in various thicknesses and formats to meet specific project requirements.

Why Choose ARM for Tantalum Ribbon?

Advanced Refractory Metals (ARM) specializes in producing high-quality tantalum ribbon tailored to industry needs. Our products are manufactured with precision to ensure optimal performance in even the most demanding applications. Contact ARM today to learn how our tantalum ribbon can support your projects and drive innovation.

Recent Comments