Tantalum electrolytic capacitors are widely used in communications, computers, aerospace, and military, as well as advanced electronic systems, portable digital products, and other fields.

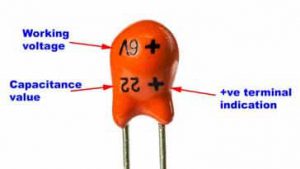

Tantalum electrolytic capacitor is made of tantalum (Ta) metal as anode material, which can be divided into foil type and tantalum powder sintered type according to different anode structures. Among tantalum powder sintered tantalum capacitors, there are tantalum capacitors with solid electrolytes and tantalum capacitors with non-solid electrolytes due to different electrolytes. The shell of tantalum electrolytic capacitors is marked with CA, but the symbol in the circuit is the same as that of other electrolytic capacitors. Compared with aluminum electrolytic capacitors, tantalum electrolytic capacitors have the following advantages.

Small volume

Because tantalum electrolytic capacitors are made of very fine tantalum powder, and the dielectric constant of the tantalum oxide film is higher than that of the alumina oxide film, the capacitance per unit volume of tantalum electrolytic capacitors is large.

Wide temperature range for use

Tantalum electrolytic capacitors commonly can work normally at the temperature of -50 ℃~100 ℃. Although the aluminum electrolytic capacitor can also work in this range, its electrical performance is not as good as that of the tantalum electrolytic capacitor.

Long life, high insulation resistance, and small leakage current

Tantalum oxide film in tantalum electrolytic capacitors is not only corrosion-resistant but also can maintain good performance for a long time.

Good impedance frequency

For capacitors with poor frequency characteristics, the capacitance will drop sharply and the loss (tg delta) will also rise sharply when the working frequency is high. However, solid tantalum electrolytic capacitors can operate above 50kHz. When the frequency of the tantalum electrolytic capacitor increases, the capacity will also decrease but by a small margin. The data show that the tantalum electrolytic capacitor capacity decreases by less than 20% at 10kHz, while the aluminum electrolytic capacitor capacity decreases by more than 40%.

High reliability

Tantalum oxide film has stable chemical properties. In addition, Ta2O5 anode substrate of tantalum can withstand strong acid and pressure, so it can use a liquid electrolyte with low resistivity of solid or acid. In this way, tantalum electrolytic capacitors have less loss than aluminum electrolytic capacitors and have good temperature stability.

Chip tantalum electrolytic capacitors are made of highly pure and extremely small homogeneous particles, which are characterized by small size, large capacity, and high frequency. In recent years, chip tantalum electrolytic capacitors have been widely used in mobile phones, DVDs and other consumer electronic products.

Please visit http://www.samaterials.com for more information.