Rare metal material technology is one of the most important subjects in the field of material science and engineering in the new century, and it is the key material for the development of high and new technology, while tantalum niobium material plays an important role in this process. The development of modern high technology, such as information technology, new energy technology, space technology, biological technology, and superconducting technology, is closely related to rare metal materials, especially tantalum and niobium.

Tantalum niobium materials have more and more development space in the field of high technology. Firstly, tantalum and niobium capacitors are expanded to the high-capacity field. Secondly, the cutting tools of cemented carbide are developing towards the direction of the super hard and fine tip, and the application market is expected to keep a steady climb. Thirdly, tantalum-niobium is applied in the aerospace industry, and tantalum-niobium alloys and other special alloys will continue to be developed steadily.

In recent years, the demand for special niobium steel continues to grow. Special superconducting materials will be widely used in magnet materials and high and new computing technologies, and are being further developed. New applications of tantalum and niobium materials will be developed continuously. According to the development process of the world’s high-tech industry, the tantalum and niobium industry will continue to grow by more than 12% in the next 5-10 years.

Main products and functional properties

At present, the main products of the tantalum and niobium industry include tantalum powder (capacitor grade, metallurgical grade), tantalum wire, tantalum carbide, tantalum, and tantalum alloy ingots, tantalum and tantalum alloy processing materials (tantalum plate, strip, tube, bar, wire), tantalum target material, tantalum oxide (industrial, optical glass, high purity), lithium tantalate single crystal; Niobium powder (capacitor grade, metallurgical grade) niobium sheet, niobium and its alloy ingots, niobium and its alloy adding materials (plate, strip, tube, rod, wire), niobium oxide (electrical grade, industrial, light glass, high purity), niobium carbide, lithium niobate single crystal, niobium and its alloy superconducting materials, etc.

About 60% of the world’s tantalum is used to make tantalum capacitors. Tantalum powder and wire are the key materials for manufacturing tantalum capacitors, which are widely used in mobile phones, computers, digital products, automobiles, aerospace electronics, and other fields. Tantalum and niobium targets are used in semiconductor devices and liquid crystal display technology, niobium oxide, niobium powder, and niobium wire are used in manufacturing ceramic capacitors and niobium capacitors.

Superalloys can be produced by adding tantalum or niobium to tungsten, molybdenum, nickel, cobalt, vanadium and iron-based alloys or by adding other metal elements to tantalum and niobium. Superalloys are important structural materials for aerospace engines, land-based airflow turbine engines, modern weapons, and harsh industrial environment facilities. Tools and drill tools made of carbides such as tantalum carbide and niobium carbide can withstand a high temperature of nearly 3000℃, and their hardness can be comparable with diamond.

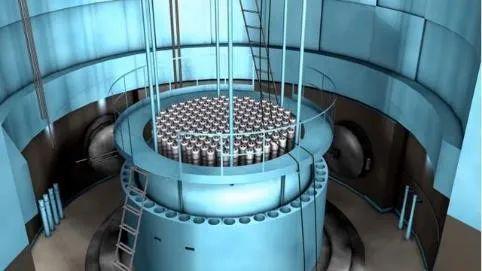

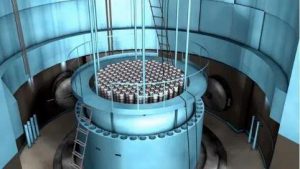

Since niobium and tantalum have good superconductivity, adding niobium and tantalum into the materials used for making wires and cables can greatly reduce the loss of electric energy and thus save electric energy. Tantalum niobium is a high-quality material resistant to acid and liquid metal corrosion. It can be used in digesters, heaters, coolers, and various devices and utensils in the chemical industry. In addition, the tantalum niobium and its alloy can also be used as nuclear reactor cladding materials and high-energy physics superconducting devices. Moreover, tantalum is ideal bio-adaptive material and is widely used in medical surgery.

Stanford Advanced Materials supplies high-quality tantalum niobium products to meet our customers’ R&D and production needs. Please visit http://www.samaterials.com for more information.